homemade injection molding machine part 2

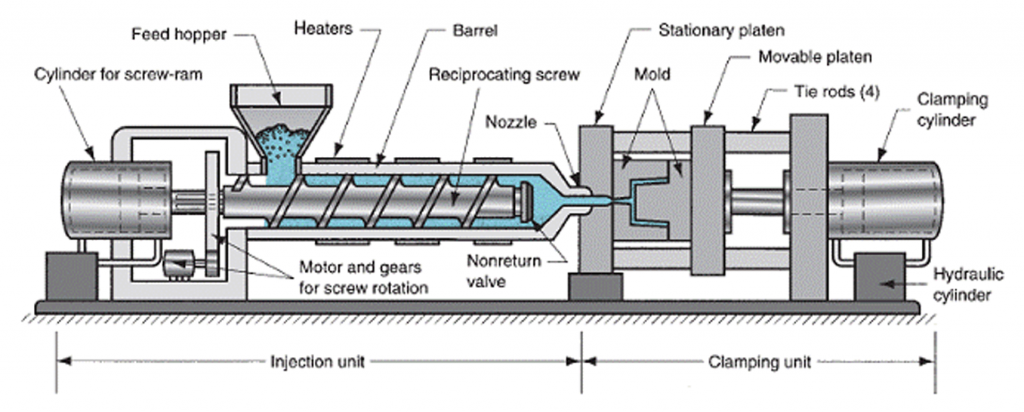

Mold a single tensile bar - 50 ton machine Mold a front end of a car - 5000 ton machine Typical sizes are 100-1000 tons For complicated parts A. 4 Injection molding machine means a machine using a plasticizer to force a charge of processed plastic material into a closed mold which produces a molded part.

Make Your Own Injection Molding Machine Make

I know Wikipedia says its a blow molding machine but Im afraid Wiki is also incorrect.

. Or by machining a desired cavity into an aluminum. A Place a mold in the machine. Snap joints should have a thickness of 05 times the wall thickness on the mold.

Do not buy a machine for a single job. A few years ago we took out first steps to have a 2-part wall mount type enclosure 35 x 5 x 125 injection molded in China and the results were amazing. Most likely this enclosure will be made of.

Two ⅛ guide pins are pressed into one half of the mold and the other holes are reamed out just slightly to 0126. Read on to see the best DIY and desktop injection molding machines. There are several videos on YouTube of the mold-a-rama in action.

Materials such as synthetic resins plastics are heated and melted and then sent to the mold where they are cooled to form the designed shape. The melt must be homogeneous and not degraded. Injection molding is a forming process using molds.

Mold manufacturing and injection service are so cheap about 2k for mold about 1 per part for reasonably sized and surfaced finish. B Make sure the sprue hole on top of the mold lines up exactly with the injection nozzle. Beyond that at right are typical prices for other auxiliary.

Here are a number of highest rated Plastic Injection Molding Machine pictures upon internet. Inexpensive homemade molds can be made using an epoxy or urethane resin. Due to the resemblance to the process of injecting.

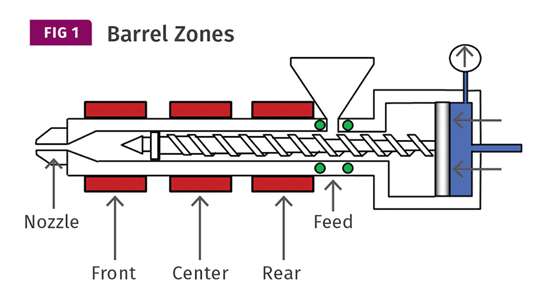

With 3D printing continually gaining ground some hackers might not see the need for traditional injection molding. Injection molding machine commonly used plunger cylinder screw cylinder. The central material dryinghandling system including five insulated drying hoppers dehumidifying dryer pumps filters and conveying system would cost about 115000.

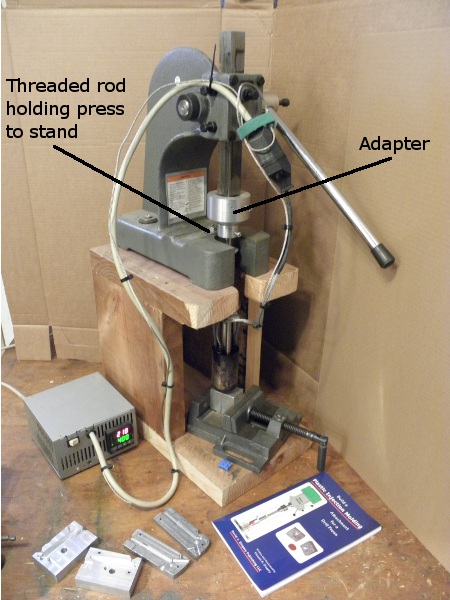

Part 1 shows the start of the build using an old tap burning machine a 60-volt power supply and a simple pulse generator. The advantages in the PLCMotion area. Feed the plastic raw material from the hopper into the barrel the plunger start to push the plastic raw material is pushed into a heating zone and then through the bypass shuttle the molten plastic through the nozzle into the mold cavity then water or oil run through the.

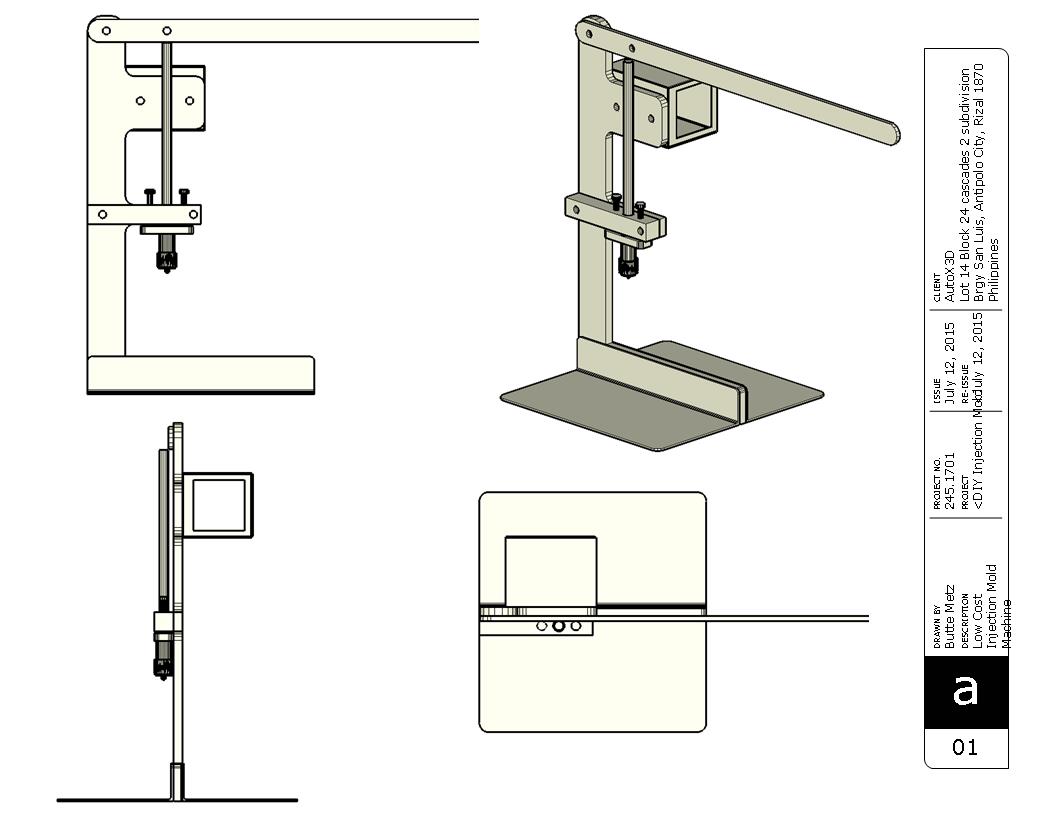

There are a few variations of two-shot molding including rotary platen movable core and overmold. Clamping force as a function of surface area. For the hardware drawing electrical schematic and parts list visit my blog.

First two 0124 holes are drilled through both blocks to hold guide pins that will ensure the mold halves are properly aligned. Published on July 7 2021. I dont understand the point of DIY injection molding.

First a draft angle needs to be added in case of snap joints. The part dimension may be achieved but the variation from shot to shot may be high leading to lower process capability. Build in flexibility because you do not know the future.

Follow the Deming principle. Wireless Data Fast Easy to Use. Designed for servo-electric hydraulic and hybrid drive.

The latter in most cases involves two separate moldsone for each materialbut can also be run with one mold two runner systems and pick-and-place part. 1 Matched metal molding means a method of molding reinforced plastics between 2. The people that use the equipment specify the equipment.

Then the parts are machined on the lathe to form the cavity for the cap. Injection molding machine and Equipment prices. After all you can tweak the code or.

It is an injection molding machine. Its submitted by handing out in the best field. This video showcases a home-made injection molding machine.

Every mold is its own peculiar beast so are the basic components of the machine. We identified it from trustworthy source. Powerful injection molding machine controller for standard and special machines.

Unless your electronic product will be marketed solely to DIYers and electronics hobbyists its going to need an enclosure. LNS Technologies Model 150A. Injection molding auxiliary equipment.

To achieve a short cycle time molders may decrease the cooling time. This was enough to experiment with the basics of both the mechanical. Building the injection stageConstructing the injection barrel piston and nozzle some pneumatics and first test of the machine moulding a small simp.

We take on this nice of Plastic Injection Molding Machine graphic could possibly be the most trending subject afterward we ration it in google lead or facebook. Most machines are horizontally oriented but vertical machines are used in some niche applications such as insert moulding allowing the. The cooling time will depend on the rate of heat removal from the cavity.

Although 3D printing is the technology used for prototyping custom plastic parts injection molding is the technology used for mass manufacturing. Injection Molding SIZING AN INJECTION MOLDING MACHINE Packing pressure 108Pa Clamping force F PA Figure 7. In case of crush ribs you need to have a 025mm interference distance between the crush rib and the fitted part.

The first two require a second injection unit two runner systems and two processes. An injection molding machine. To specify a machine break it down into its component parts.

C Clamp the mold in place by turning the vise handle clockwise. In the case of crush ribs however a draft angle is not needed. Injection moulding machine moulds can be fastened in either a horizontal or vertical position.

It consists of two main parts an injection unit and a clamping unit Operation. With XMold Beckhoff has developed a turnkey system solution for controlling complex applications in hydraulic servo-electric and hybrid injection molding machines.

Make Your Own Injection Molding Machine Make Plastic Moulding Diy Molding Metal Working Projects

Homemade Injection Molding Machine Part 1 Youtube

Tips For Plastic Injection Molders Topworks Plastic Polding

Injection Molding Machine Part 2 The Extruder Screw Youtube Injections Machine Parts Molding

Diy Of Small Pneumatic Desktop Injection Mold Machine Youtube

Injection Molding Process Xcentric Mold Engineering

Urethane Resin Casting A Joby Gorilla Pod Hotshoe Camera Mount Reaction Injection Molding Rim Part 2 Urethane Resin It Cast Resin Casting

Design And Fabrication Of Hand Injection Molding Machine Mechanical Project Youtube

Diy Plastic Injection Molder Openbuilds

Home Plastic Injection Molding

Building A Better Diy Injection Moulding Machine Part 2 Youtube

Homemade Plastic Injection Machine Faster Than 3d Printing Youtube

Diy Plastic Injection Molding Machine Test Youtube

Home Plastic Injection Molding With An Epoxy Mold 7 Steps With Pictures Instructables

Diy All Electric Plastic Injection Molding Machine 3d Cad Model Library Grabcad

Injection Molding How To Set Barrel Zone Temps Plastics Technology

Build A Plastic Injection Molding Attachment For A Drill Press Vincent R Gingery Vincent R Gingery Vincent R Gingery 9781878087317 Books

Pin By Arbi Oussama On 3d Printing Plastic Injection Moulding Machine Plastic Injection Molding Plastic Moulding